Extraction Arms

Extraction arms sometimes referred to as snorkel arms, are the recommend method for providing point source capture. Benefits of point source capture include reduced air volume, energy savings, effective contaminate containment, user friendly, low purchase cost compared to custom hood design, and increased work radius. Extraction arms are used in almost every industry for effective control of welding fumes, pharmaceutical dust, gases, oil mist, grinding dusts, caustic vapors and nuisance dust.

Alsident

Customizable arms for a wide variety of applications. Ranging from 2-4 inches in diameter, in Aluminum, Chemical Resistant and Antistatic styles. With an array of hoods for each size, combines with hanging and standing mounting options they are an excellent customizable solution for lower CFM needs.

Aluminum

Offering a durable coating with polypropylene joints These arms offer a wide range of motion and working area.

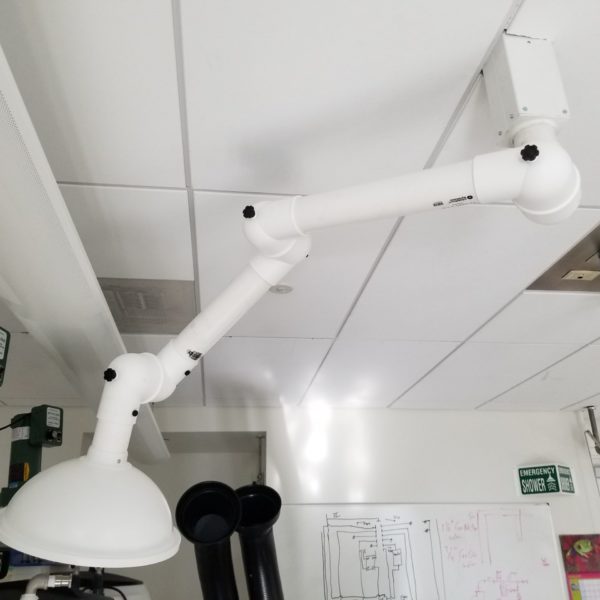

AQC

Powder Coated Steel arms ranging from 3-8 inches in diameter. Stainless Steel with Anodized Aluminum exterior joints are also available.

Chemical Resistant

Provide a different level of chemical resistance to help keep labs safe while working with corrosive or reactive chemical compounds.

Hose

Great for small areas with maximum flexibility to the workspace, hose-based arms are a cost-effective solution for welding cabins and schools.

Plymovent

Powder Coated Aluminum, Plastic, and Hose based arms with a focus on welding and cutting applications. Table, wall, ceiling, boom and rail mounting available

Powder Coated

Powder coated arms cover a wide of sizes and styles for use in a number of manufacturing environments.

Stainless Steel

304 stainless arms offer a great combination of chemical resistance and safety in the food and Flavor and Pharmaceutical world.